As a PVC manufacturer, you are facing a new kind of pressure. It’s not enough to deliver high-performance vinyl; customers and regulators now demand to know the entire lifecycle of your product, from the carbon footprint of your raw materials to the ethics of your supply chain.

Our team provides the data and certifications you need to satisfy your auditors. Here are the 4 key sustainability pillars you should demand from your partners.

1. Cleaner Manufacturing

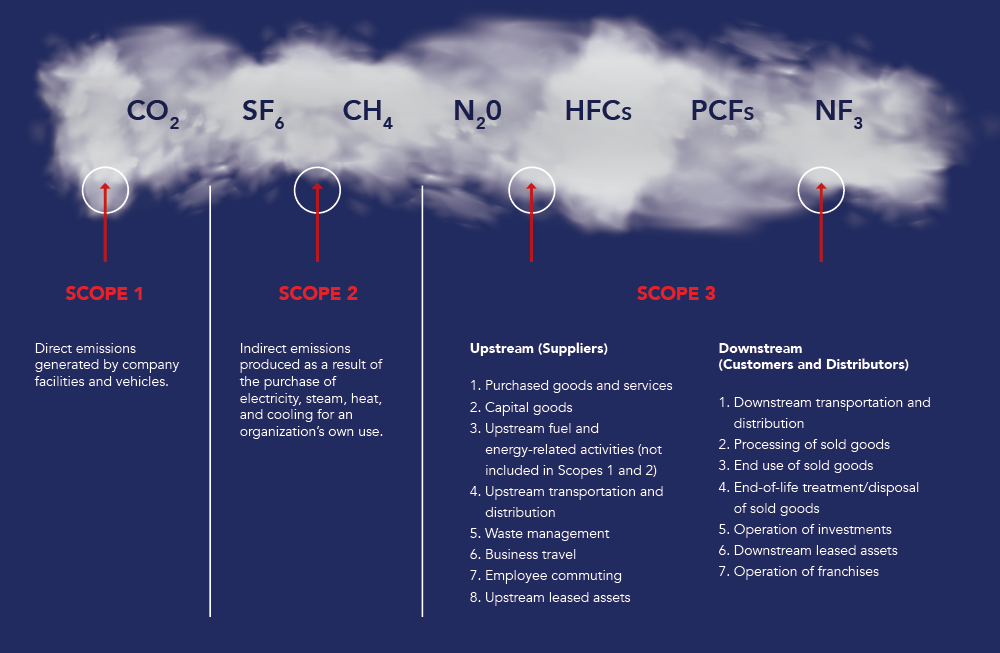

If you supply major brands, you are likely already reporting "Scope 3" emissions (the carbon footprint of your supply chain). According to the EPA, supply chain emissions often account for the majority of an organization's total greenhouse gas (GHG) emissions.

- Challenge: You cannot lower your company's total carbon footprint if your raw material suppliers rely on fossil-fuel-heavy manufacturing or generate high volumes of waste.

- Solution: We attack this from two angles. First, our facility is powered by solar panels, allowing us to generate our own electricity. Second, we have developed processes to significantly reduce hazardous wastewater and landfill waste during our liquid mixed metal production process.

- Benefit: You get a double win: a lower carbon footprint for your raw materials and the assurance that your supply chain isn't contributing to water pollution risks.

2. Verified Transparency

Greenwashing is a major risk in the chemicals industry. Your stakeholders need proof, not promises.

- Challenge: How do you verify that a supplier is ethical and environmentally responsible without spending months auditing them yourself?

- Solution: We back up our claims with independent data. We have completed the EcoVadis assessment, earning a "Committed" rating for our ethics and sustainable procurement. We also hold ISO 14001:2015 certification, demonstrating that we have rigorous systems for measuring and improving our environmental performance. We’ve also completed ISO 14040/14044 Life Cycle Assessment (LCA) work for our Solid Calcium/Zinc and Liquid Barium/Zinc stabilizers.

- Benefit: You get a verified, audit-ready partner that passes the strict vendor vetting requirements of Fortune 500 companies.

3. Regulatory Future-Proofing

Regulations like REACH (Europe) and Prop 65 (California) are constantly tightening the list of allowable chemicals. The Prop 65 list now contains approximately 900 naturally occurring and synthetic chemicals known to cause cancer or reproductive harm.

- Challenge: Using "borderline" chemistries puts your product at risk of being banned, fined, or labeled with consumer warning stickers.

- Solution: Our technology is driven by initiatives such as REACH, RoHS, Conflict Minerals, and Prop 65. We continuously develop products that meet these ever-changing regulatory demands to protect our customers from compliance gaps, offering Low-VOC and heavy-metal-free options that meet the strictest indoor air quality standards.

- Benefit: You can market your products with confidence, avoiding the regulatory headaches that come with using legacy heavy metals or restricted substances.

4. Recycling

The industry is moving toward higher recycled vinyl content. According to The Vinyl Institute, more than 1.1 billion pounds of vinyl are recycled annually in the U.S. and Canada, but manufacturers often hesitate because recycled material can be unpredictable.

- Challenge: Increasing recycled content often leads to processing instability or product degradation, making it hard to hit circular economy targets.

- Solution: We actively support the circular economy by engineering additives specifically for Post-Industrial Content (PIC) and Post-Consumer Recycled (PCR) materials. Our technologies are designed to enhance processing and durability, ensuring that your recycled compounds meet the same high standards as virgin PVC.

- Benefit: You can hit your internal recycling targets and reduce waste without compromising on quality, extending the lifecycle of your materials while maintaining peak performance.

Ready to Clean Up Your Supply Chain?

Sustainability doesn't have to be a burden. It can be your competitive advantage. Whether you need life cycle assessment data for a green building project or a compliance partner for a legacy line, we have the chemistry to get you there.